Shaping the Future with DLP 3D Printing: A Comprehensive Guide

With the advancement of technology, 3D printing has become a popular method for manufacturing and prototyping products. One of the latest technologies used in 3D printing is DLP, which offers a number of advantages over traditional 3D printing methods. So whether you’re a 3D printing enthusiast or someone looking to learn more about this cutting-edge technology, join us as we explore the world of DLP 3D printing!

Digital Light Processing (DLP) 3D printing is a powerful technology that has revolutionised the manufacturing industry. Unlike traditional 3D printing methods, which rely on layer-by-layer deposition of material, DLP 3D printing uses light to selectively cure liquid resin, creating complex, high-resolution 3D objects in a fraction of the time. DLP 3D printing has enabled new possibilities in industries such as healthcare, automotive, and aerospace by allowing for the creation of intricate and precise parts that were previously impossible to produce.

In this post, we will dive into the specifics of DLP 3D printing, how it works, its benefits, and some of the industries that are currently utilising this technology. Whether you’re a hobbyist or a professional in the manufacturing industry, we hope this post will provide you with valuable insights into the world of DLP 3D printing. So, let’s get started!

What is DLP 3D Printing?

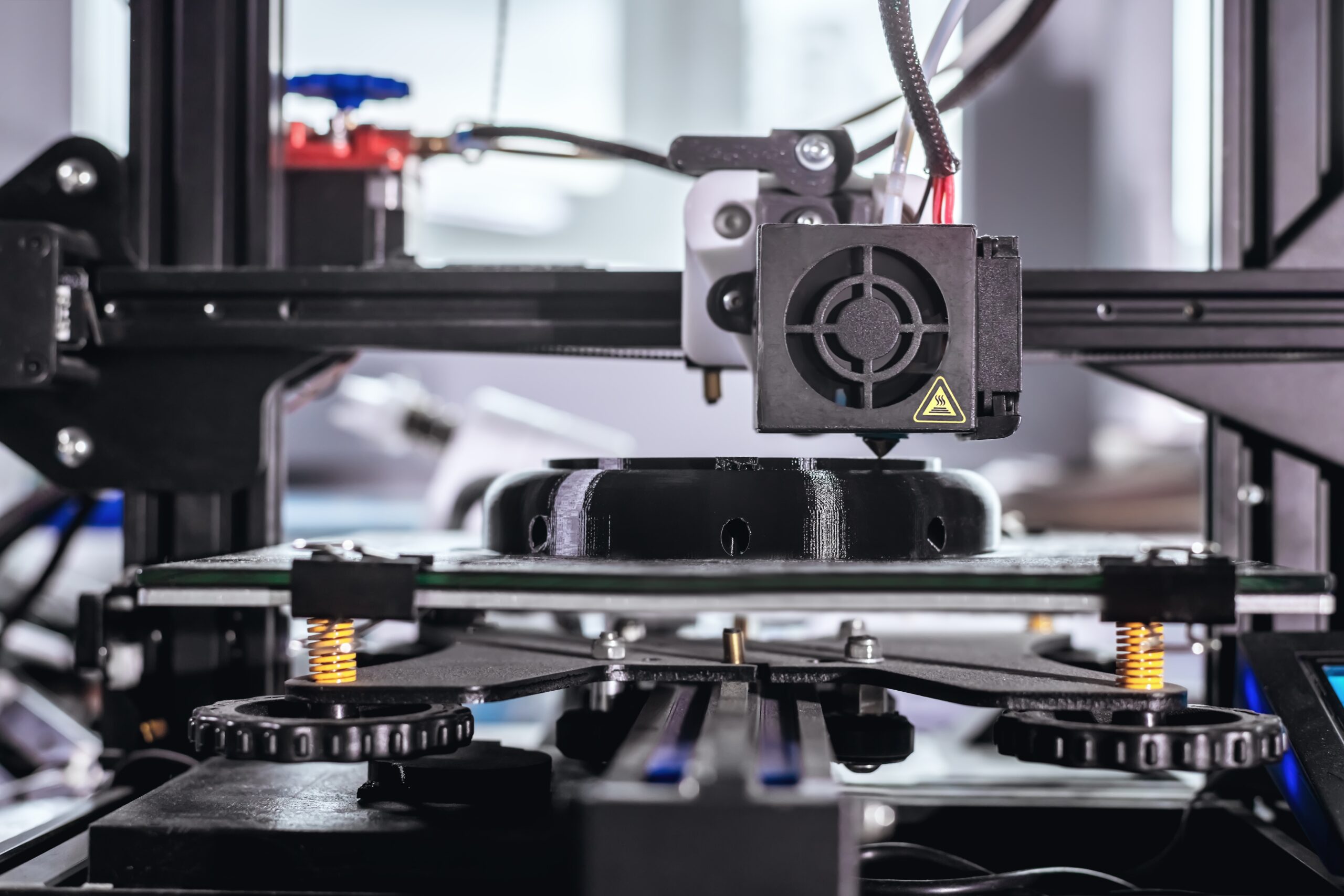

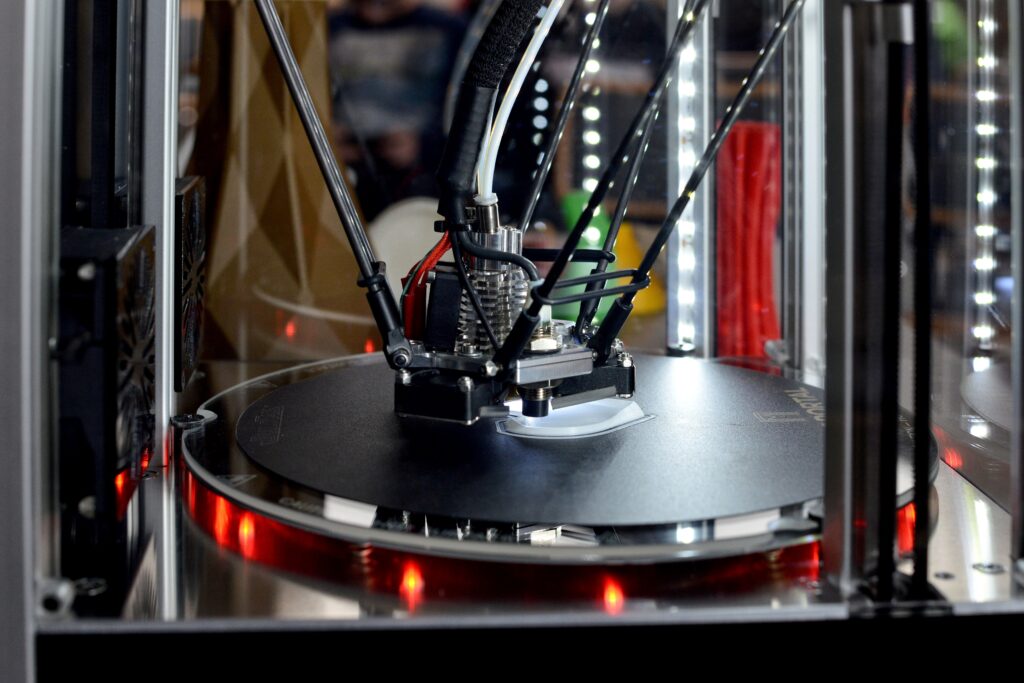

Digital Light Processing (DLP) 3D printing is a manufacturing process that uses light to selectively cure liquid resin, creating complex 3D objects with high resolution and precision. The process works by projecting an image of the 3D model onto a vat of liquid resin using a light source, such as a projector or a laser. The light causes the resin to cure and harden, forming a solid layer that corresponds to the shape of the object being printed. The build platform is then lowered slightly, and the process is repeated to create the next layer, with each layer bonding to the previous one until the object is complete.

Compared to traditional 3D printing methods, DLP 3D printing is faster, more accurate, and can produce parts with more intricate details. It is also suitable for producing small batches of parts, making it ideal for prototyping and manufacturing customised objects. Additionally, DLP 3D printing can work with a range of materials, including resins that can be optimised for specific applications. As a result, DLP 3D printing has become a popular manufacturing technique in industries such as healthcare, automotive, and aerospace, where precision and speed are essential.

Working of DLP 3D Printing

Digital Light Processing is a 3D printing technique that employs a digital light projector to treat photopolymer resin. In this procedure, the photopolymer resin is cured using a safelight (light bulb). This projector cures a photopolymer resin layer by layer. Furthermore, curing the selected areas to be solidified based on the 3D printer model while leaving the surrounding areas uncured. After the first layer is finished, the portion is raised one layer height and the process is repeated.

Digital Light Processing (DLP) 3D printing is a type of resin-based 3D printing that uses a process called photopolymerization to create three-dimensional objects. Here is how DLP 3D printing works:

Preparation of the 3D Model: The first step is to prepare the 3D model using computer-aided design (CAD) software. The model can be downloaded from an online database, created from scratch using CAD software or scanned using a 3D scanner.

Preparation of the Resin: The next step is to prepare the liquid resin, which is a photosensitive material that hardens when exposed to light. The resin is poured into a container that is located below the DLP projector.

Projection of the Layers: The DLP projector shines a light onto the surface of the liquid resin. The light solidifies the resin in the pattern of the first layer of the 3D model.

Raising the Build Platform: Once the first layer is solidified, the build platform is lowered by the thickness of one layer, and the process is repeated for the next layer. The DLP projector projects the light onto the resin in the pattern of the next layer of the 3D model, and the resin is solidified again.

Completion of the Print: Once all the layers are solidified, the object is complete. The build platform is raised to the top of the resin tank, and excess resin is drained away. The object is then removed from the build platform and cleaned with a solvent to remove any remaining uncured resin.

DLP 3D printing offers high accuracy, resolution, and speed compared to other 3D printing technologies. It is ideal for creating small, intricate objects with fine details. However, the process requires the use of liquid resin, which can be messy and requires proper safety precautions during handling.

Benefits of DLP 3D Printing

Digital Light Processing (DLP) 3D printing has several advantages over traditional 3D printing methods. Here are some of the key benefits of using DLP 3D printing:

High Resolution

DLP 3D printing uses light to cure liquid resin, allowing for the creation of objects with very high resolution and precision. This makes it possible to produce complex, detailed parts that would be difficult or impossible to create using traditional 3D printing methods.

Speed

DLP 3D printing is faster than many other 3D printing methods because it cures an entire layer of resin at once, rather than printing each layer one at a time. This makes it ideal for producing large quantities of parts quickly.

Accuracy

DLP 3D printing is highly accurate and can produce parts with very tight tolerances. This makes it ideal for creating parts that need to fit together precisely, such as gears or other mechanical components.

Versatility

DLP 3D printing can be used to create a wide range of objects, including complex geometries and parts with intricate details. It can also be used with a variety of materials, including resins that are optimised for specific applications.

Cost-effectiveness

DLP 3D printing can be a cost-effective way to produce small to medium-sized batches of parts. Because it can create parts quickly and with high accuracy, it can be a more efficient manufacturing method than traditional manufacturing techniques.

Overall, DLP 3D printing offers a range of advantages over other 3D printing methods and traditional manufacturing techniques, making it a popular choice for a wide range of applications.

Applications of DLP 3D Printing

Digital Light Processing (DLP) 3D printing has a wide range of applications across various industries, including:

Healthcare

DLP 3D printing is used to produce anatomical models for surgical planning and training, as well as prosthetics, orthotics, and other medical devices. The high resolution and accuracy of DLP 3D printing make it ideal for creating customised, patient-specific devices.

Jewellery

DLP 3D printing is used to produce high-detail jewellery models, such as rings, pendants, and earrings, that can be cast in metal. The ability to create intricate details and complex geometries makes DLP 3D printing a popular choice in the jewellery industry.

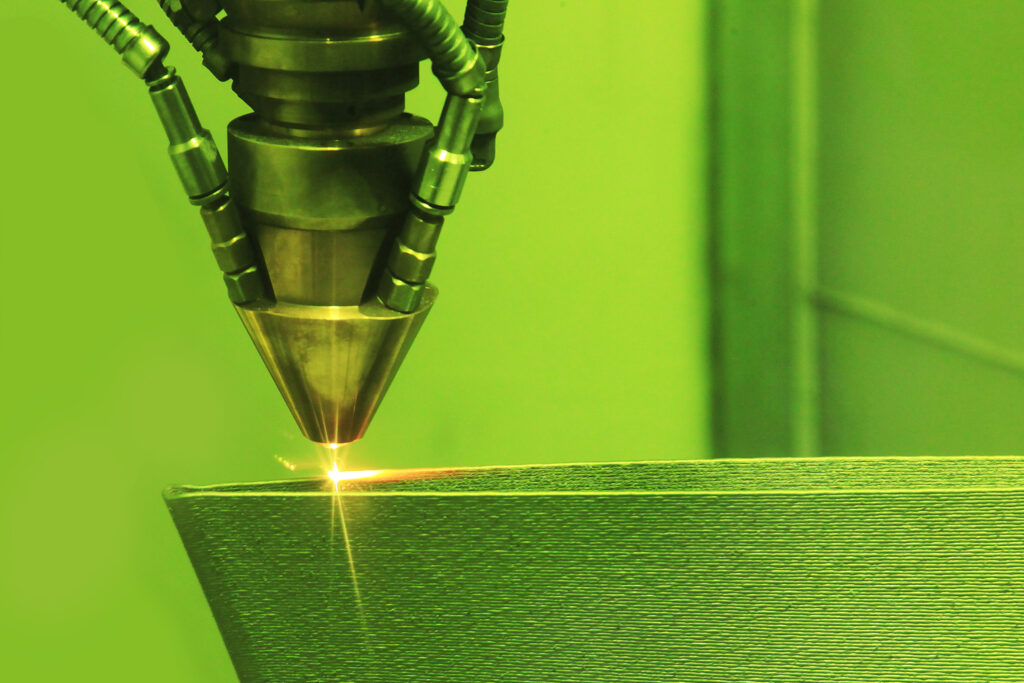

Aerospace

DLP 3D printing is used to produce complex components and prototypes for aerospace applications. The speed and precision of DLP 3D printing make it possible to create parts with tight tolerances and intricate geometries that would be difficult or impossible to produce with traditional manufacturing methods.

Automotive

DLP 3D printing is used to produce prototypes, moulds, and tooling for the automotive industry. The ability to create complex shapes and designs quickly and accurately makes DLP 3D printing a valuable tool in the automotive design and manufacturing process.

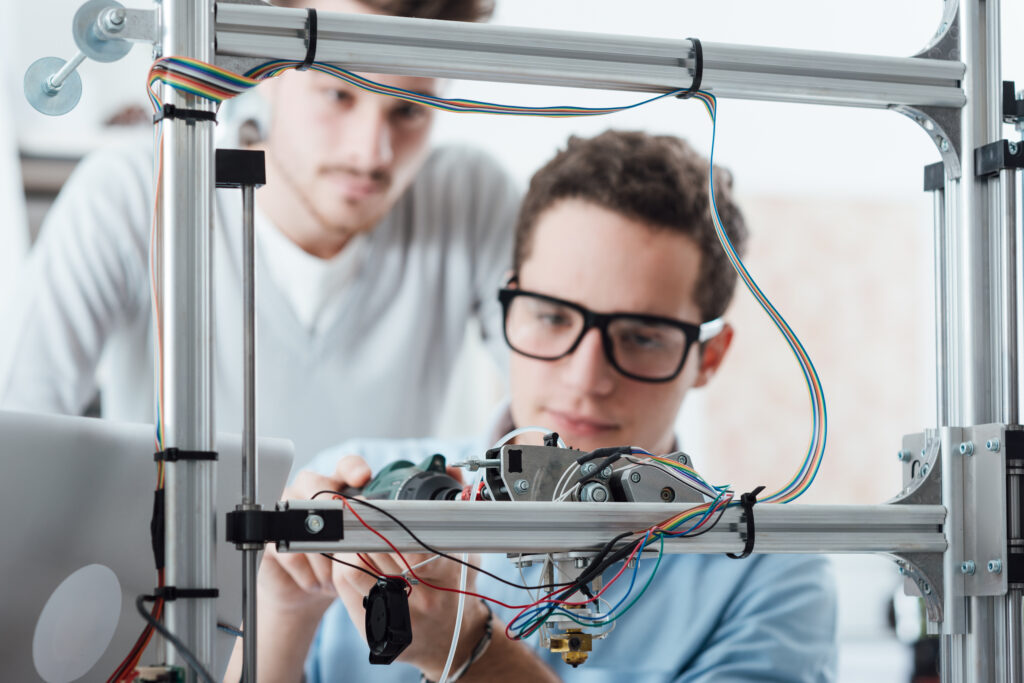

Education

DLP 3D printing is used in education to teach students about 3D modelling and design. Students can use DLP 3D printing to create their designs and see them come to life in physical form, helping to bring their ideas to reality.

Limitations of DLP 3D Printing

Overall, DLP 3D printing has a wide range of applications and is becoming increasingly popular in various industries, thanks to its speed, precision, and versatility. As technology continues to evolve, it is likely that even more applications will emerge in the future.

While Digital Light Processing (DLP) 3D printing has many advantages, there are also some disadvantages to consider. Here are some of the limitations of DLP 3D printing:

Limited Materials

DLP 3D printing is currently limited to using photopolymer resins, which can be more expensive than traditional 3D printing filaments. The variety of resins available is also more limited than other materials, such as plastics or metals.

Post-processing Requirements

DLP 3D printed objects typically require post-processing, such as washing, curing, and sanding, to remove excess resin and improve surface finish. This can add time and labour costs to the production process.

Limited Build Size

DLP 3D printers are typically limited in the size of the objects they can produce due to the size of the build platform and the need for support structures. This can make it challenging to produce larger objects or batches of parts.

Limited Resolution

While DLP 3D printing can produce high-resolution parts, the resolution is limited by the size of the pixels in the projected image. This can result in visible layer lines or a loss of detail in very small features.

UV Sensitivity

DLP 3D printing resins are sensitive to UV light, which can affect the mechanical properties of the finished parts over time. This can lead to reduced durability or structural integrity in some applications.

Overall, while DLP 3D printing has many advantages, it is important to consider these limitations when deciding if it is the right manufacturing method for a particular application.

Innovate Faster with PCBWay’s DLP 3D Printing Partnership

DLP 3D printing is a popular technology for creating high-resolution, intricate 3D models. When it comes to choosing a DLP 3D printing partner, there are several factors to consider to ensure that you are getting the best quality prints, timely delivery, and affordable pricing. Whether you are a business looking to produce prototypes or a hobbyist seeking to bring your creative ideas to life, choosing the right DLP 3D printing partner can make all the difference for the success of your project.

When it comes to choosing a DLP 3D printing partner, PCBWay is a company worth considering. As a trusted provider of PCB fabrication and assembly services, PCBWay has expanded its services to include DLP 3D printing. Here are some reasons why you should consider PCBWay as your DLP 3D printing partner:

Quality: PCBWay prides itself on providing high-quality DLP 3D printing services. With advanced DLP technology and a team of experienced technicians, PCBWay ensures that every print is of the highest quality with excellent accuracy and resolution.

Customization: PCBWay offers a wide range of customization options, including the choice of materials, colours, and finishes. This allows you to tailor your 3D prints to your specific needs and preferences.

Speed and Timeliness: PCBWay has a quick turnaround time for DLP 3D printing projects, with a lead time of 3-5 days. This ensures that you can receive your prints in a timely manner without sacrificing quality.

Competitive Pricing: PCBWay offers affordable pricing for DLP 3D printing services, making it accessible for businesses and individuals with varying budgets.

Customer Service: PCBWay has a dedicated customer service team that is available to answer any questions or concerns you may have about your project. They also provide regular updates on the status of your project and work with you to ensure that you are satisfied with the final product.

Overall, PCBWay is a reliable and trustworthy DLP 3D printing partner that offers quality, customization, speed, affordability, and excellent customer service.

PCBWay’s Standard Surface Finishes

PCBWay is a company that offers both PCB fabrication and assembly services as well as DLP 3D printing services. In their DLP 3D printing service, they offer a range of standard surface finishes including smooth, glossy, textured, and painted finishes. These finishes allow customers to choose the best option for their specific application requirements, whether that be a smooth matte finish or a shiny, polished surface.

Spray Painting

Depending on the colour scheme the user specifies, PCBWay offers many painting choices. This includes varnish, leather paint, high-gloss paint, paint that mimics electroplating, matte paint, and more.

Polished

To satisfy the actual needs of clients, the surface texture is polished in a number of ways. To increase transparency and light transmittance, the transparent components can be appropriately polished.

Electroplating

Electroplating services are offered by PCBWay, which increase the parts’ overall strength, give them a surface texture that looks like metal, and provide them with specific metal properties.

Inlay Nut

Internal thread processing occurs at the precise bottom hole position that needs to be done.

Glazing Assembly

In order to better replicate the appearance of handmade goods, this feature has a glazed surface on the component. To assure the entire presentation of the product, have solid assembly experience.

Reinforced Coating

The unique outer coating processing capability increases the product’s structural strength, lowers external wear, and can better prevent damage brought on by typical use and storage.

Testing Service

A wide range of measuring tools offers accurate measurement services that meet the exact needs of customers.

Overall, PCBWay offers a range of standard surface finishes in their DLP 3D printing service, allowing customers to choose the finish that best suits their specific needs and requirements. Whether you need a smooth, matte finish or a shiny, polished surface, PCBWay has you covered.

Conclusion

In conclusion, DLP 3D printing is a highly advanced and efficient printing technology that offers several benefits over other 3D printing techniques. It offers high accuracy, speed, and resolution, making it ideal for creating intricate and detailed objects. Additionally, it offers a range of material options, including resins that can produce objects with various colours and textures. While it may be relatively expensive and require specialised equipment, the advantages of DLP 3D printing make it an excellent choice for a wide range of applications, including prototyping, manufacturing, and even art and design. With ongoing advancements in technology, DLP 3D printing is likely to become even more accessible and widely used in the coming years, revolutionising the way we create objects and bringing new possibilities to the field of 3D printing.